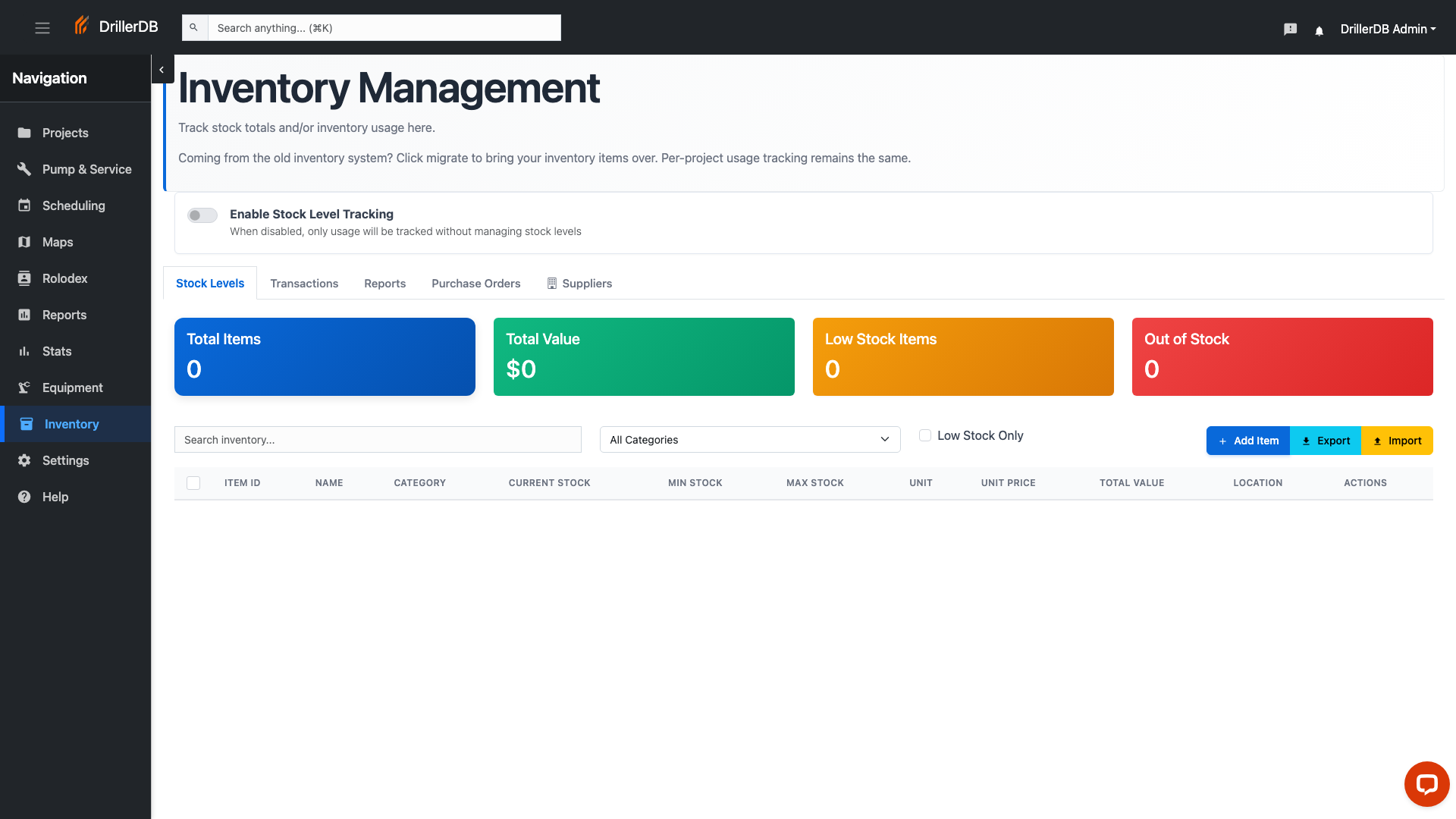

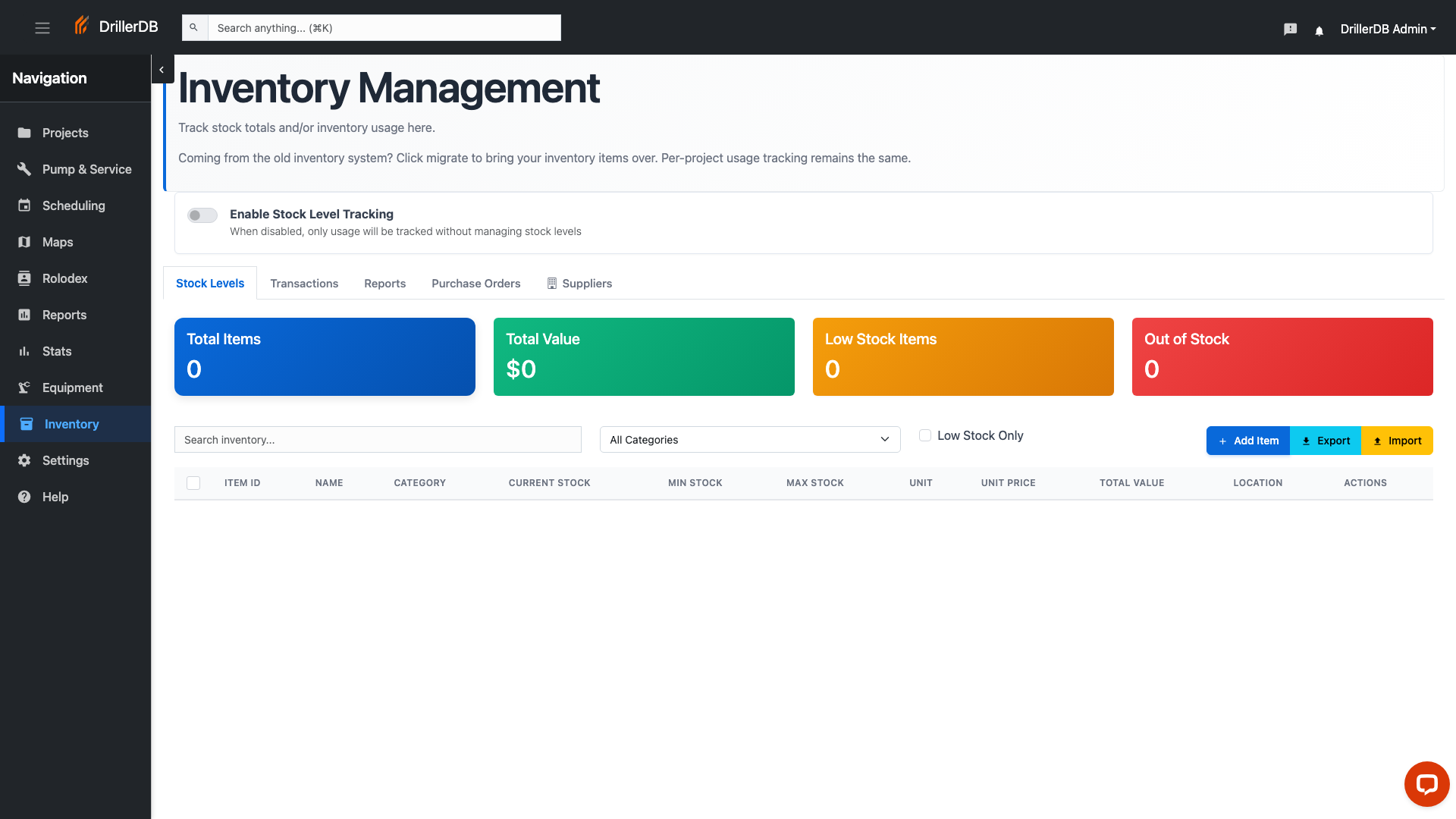

Inventory tracking

Track casing, pipe, pumps, and supplies by project and across your company. Know what you have, what you've used, and when to reorder.

Track casing, pipe, pumps, and supplies by project and across your company. Know what you have, what you've used, and when to reorder.

Running out of casing on a job costs time and money. DrillerDB tracks inventory usage per project so you always know what's on hand and what to order.

Record materials used on each job for accurate costing and reordering.

See total inventory across all locations and trucks.

Get notified when items fall below reorder thresholds.

Explore the key capabilities that make this feature essential for drilling operations.

Outline the core workflow that this feature unlocks for drilling teams.

Call out any automation, compliance, or customer-facing outcomes you deliver.

Explain how back-office staff, field crews, and leadership stay aligned.

Translate abstract capability into specific day-to-day workflows. Replace these cards with customer stories or internal playbooks.

Explain how schedulers, dispatchers, or project managers rely on this feature to move faster.

Describe what happens in the field and how data flows back into DrillerDB.

Call out any reporting, compliance, or financial workflows supported here.

See how inventory tracking prevents stockouts and improves job costing.